Laminators Inc. has Unveiled a New Non-Combustible Insulated Glazing Panel

InfernoShield™ Non-Combustible Insulated Glazing Panel

Hatfield, PA – Throughout the last year, the Laminators Incorporated team has been eagerly working to expand their insulated glazing product line for the glass and glazing industry. After much planning, designing, and testing Laminators is ready to introduce us to the newest member of their architectural product line—InfernoShield™.

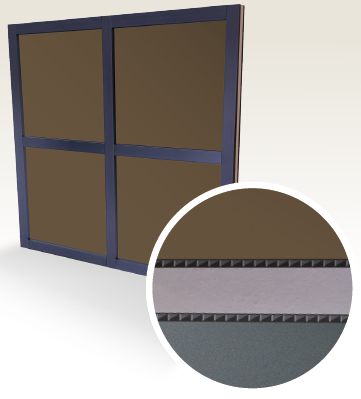

InfernoShield™ is a new non-combustible insulated glazing panel designed to provide superior fire performance when installed in window, glazing, and curtain wall systems. The panels fit into any standard 1 in. glazing pocket and curtain wall system.

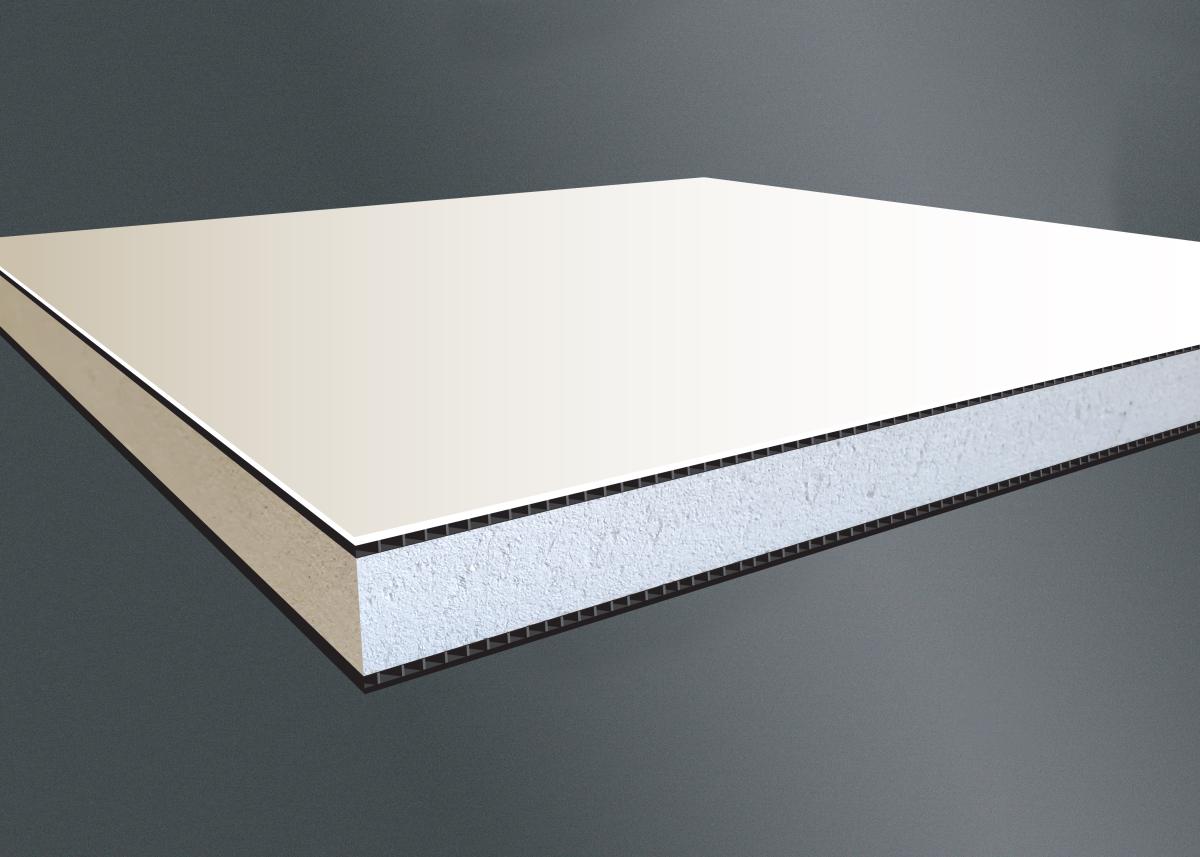

InfernoShield panels are constructed of a Calcium Silicate core, sandwiched between extruded profile stabilizers with a finished aluminum sheet on each face. The finished product has a 1 in. overall thickness, provides an R-Value of 2.14 per in. (comparable to a typical 1 in. insulated glass unit), and weighs 2.77 lbs./sq. ft (up to 40% lighter than other non-combustible in-fill panels).

Panels meet non-combustible requirements of IBC Section 703.5, as well as have a class-A rating with a zero-flame spread per ASTM E84. The non-combustible panel composition eliminates the need to meet NFPA 285 requirements.

InfernoShield panels are available in multiple color options, including PVDF/Kynar 500®, polyester or anodized, as well as either a smooth or stucco-embossed finish, to create a highly decorative and durable surface.

They are available in stock sheets or cut-to-size, making them an excellent option for various glass and glazing applications, including—curtain walls, window systems, window replacement, opaque glazing, storefronts, in-fill panels, high-rise and commercial construction.

InfernoShield has up to a 30-year finish warranty and a 5-year panel construction warranty.

In addition to their new non-combustible insulated panel, Laminators also offers a standard flat insulated glazing panel, Thermolite™, as well as fabricated options that provide additional R-Value, give new aesthetics and to create hairline joints between panels. The fabricated options include Thermolite™ U-MAX [a 7-ply, rabbet edge panel designed to provide increased insulation on the panel’s interior face]; Thermolite™ SE [provides new aesthetics with the ability to adjust the reveal created between the face of the mullion and the face of the panel]; and Thermolite™ WE [an edge treatment allowing for metal-to-metal butt-glazed joints to create hairline joints]. Thermolite glazing panels are constructed with an insulating foam core sandwiched between two corrugated, stabilizers and finished aluminum sheets. These glazing panels add a highly decorative and durable surface with excellent insulating properties. They are designed to easily fit into any standard or custom glazing system.

All the insulated glazing panels mentioned above are manufactured with the highest quality products at the Laminators Inc. facility in Hatfield, Pennsylvania, USA. With building and energy efficiency codes becoming even more stringent, InfernoShield and Thermolite insulated glazing panels are a smart solution for your next project.