Laminators is one of very few manufacturers who offer various fully designed, integrated, and tested ACM panels and installation systems… and we’re here to help you throughout the entire process!

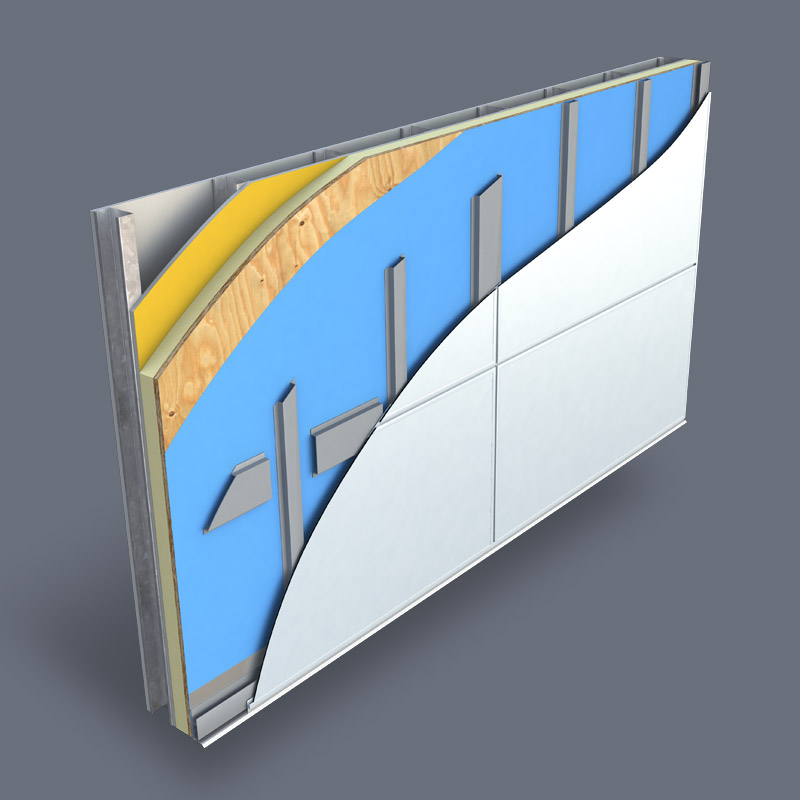

We offer different panel installation systems to give you the look and performance you need at the budgeted cost you require. Panels can be measured and cut at the job site or in a shop environment. Cut-to-size panels can be ordered to minimize waste and reduce labor and material expenses.

To provide you with the most flexibility, Laminators Inc. has both Field-Fabricated and Shop-Fabricated installation systems —

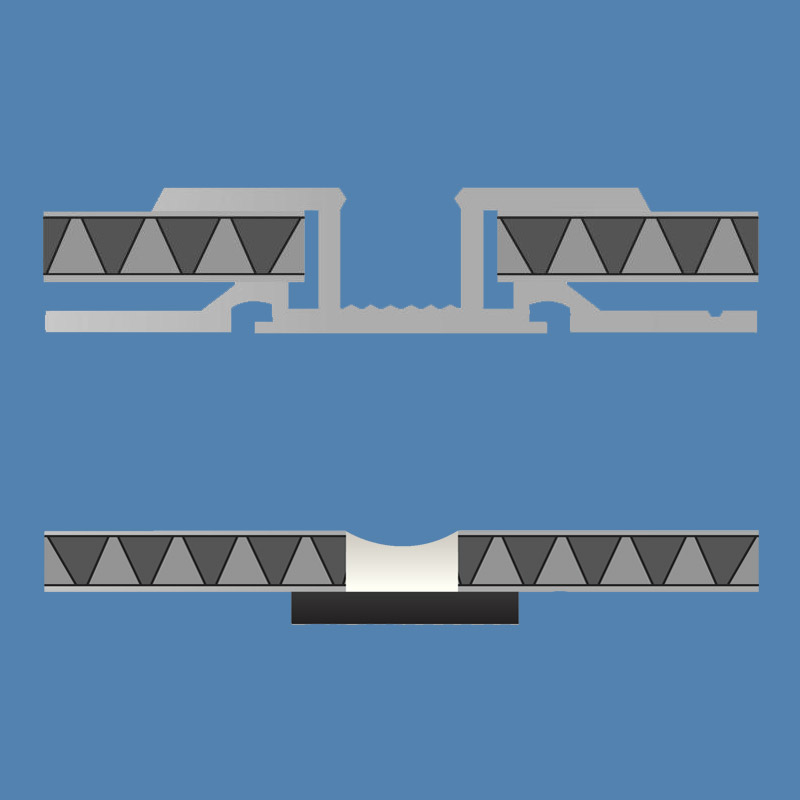

Field-Fabricated Installation Systems:

Designed for fast, easy fabrication directly on the job site, saving time and money by allowing installers to adapt to as-built conditions during installation.

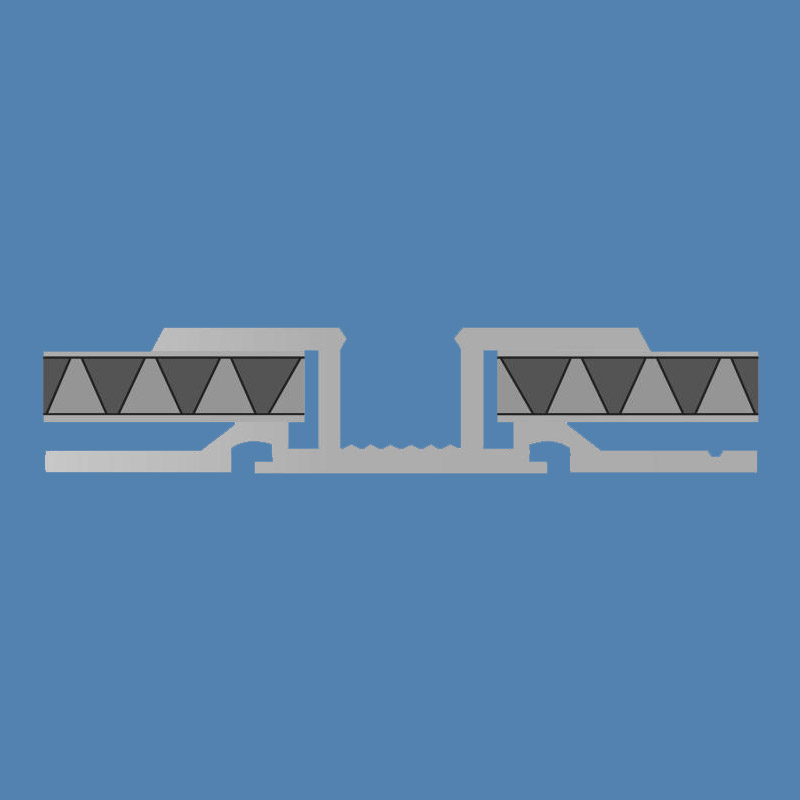

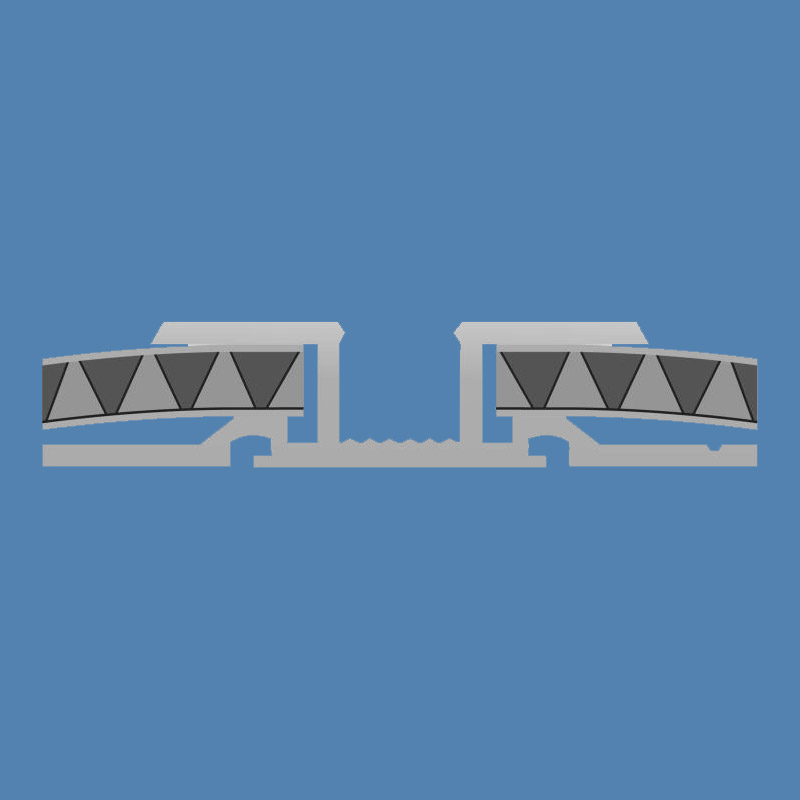

• 1-Piece, Tight-Fit Molding

• 1-Piece, Tight-Fit Molding Legacy

• Clip & Caulk™

• Clip & Caulk Legacy

Shop-Fabricated Installation Systems:

Designed to be prefabricated in our shop and delivered directly to the job site, or an experienced fabricator can fabricate the panels in a shop environment.

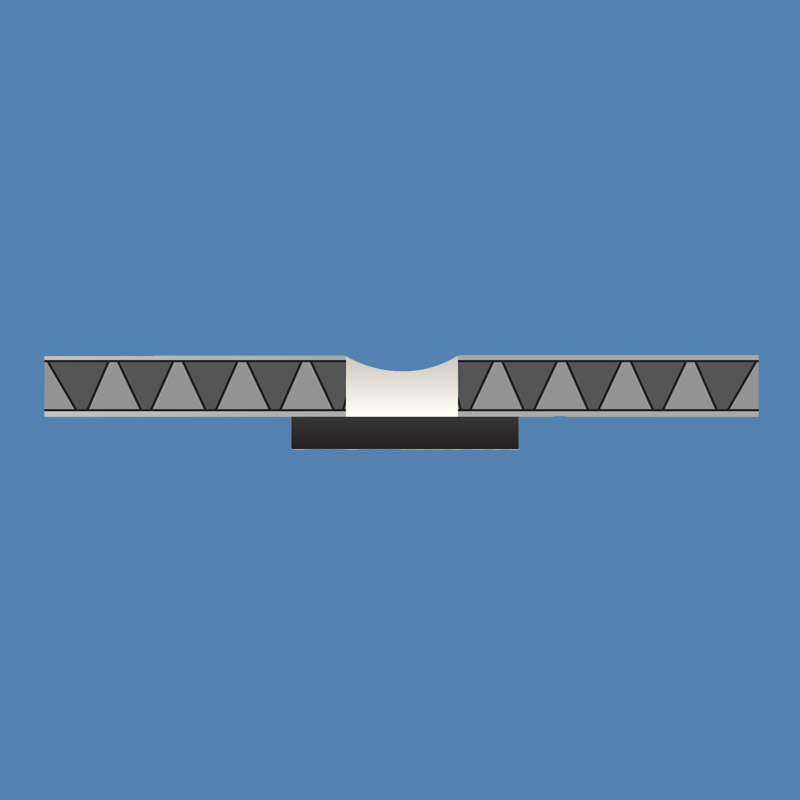

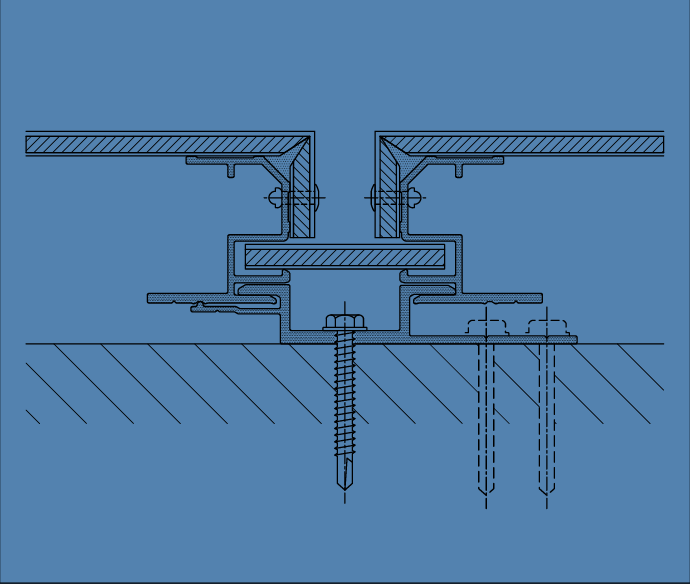

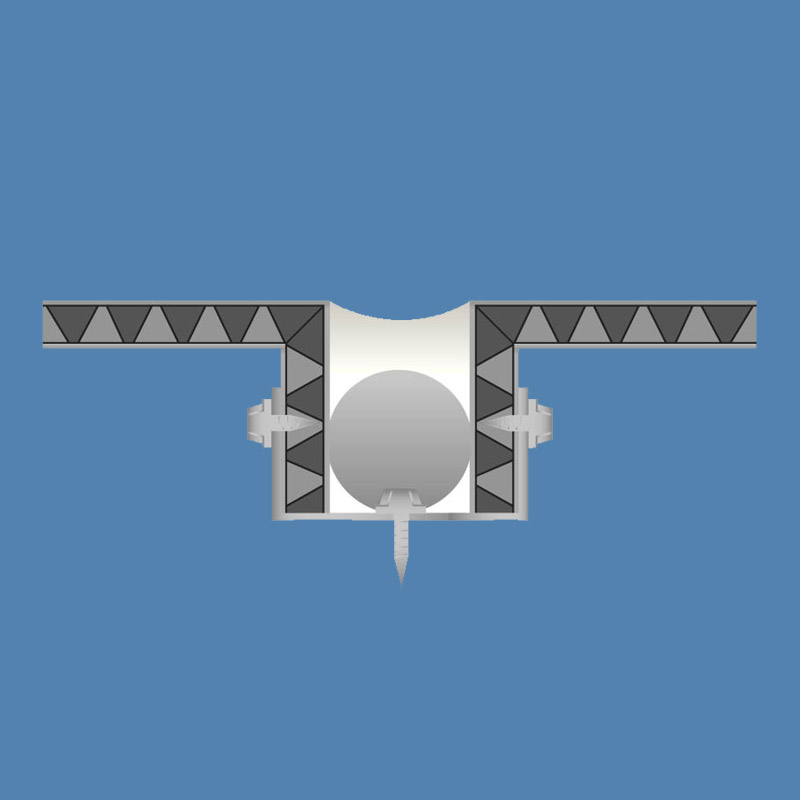

• AdaptaClad® RS

• Rout & Return

Laminators Inc. has worked feverishly to launch AdaptaClad® RS (rainscreen), a new and enhanced proprietary installation system that has replaced our existing Dry Seal installation system. AdaptaClad RS is an extremely adaptable and easy-to-install system that is designed to utilize our NEW Omega-Lite® FR (fire-resistant) ACM panel. This new system is intended to provide significant time and labor savings to fabricators and installers.

Omega-Lite installed in both our field-fabricated and shop-fabricated installation systems meet NFPA 285, Florida Product Approval (FL #17652-R3), and Miami-Dade County Product Control (NOA #23-0911.07) requirements.

In addition, Laminators maintains an ICC-ES Listing Report for Omega-Lite ACM panels as well as our Tight-Fit Molding system over Omega CI and Clip & Caulk system over both Omega CI and gypsum sheathing.

Legacy Field-Fabricated Installation Systems

A “Legacy Version” of the 1-Piece, Tight-Fit Molding installation system and Clip & Caulk installation system. These systems are ideal for architectural features and when building codes do not require the high performance as designed in other installation systems.