While our composite panels are most recognized in the commercial construction and sign-making industries, we have the ability to provide customizable composite panel options to satisfy a wide variety of applications and their unique requirements.

With a wide range of standard Kynar or polyester colors and finishes to choose from, the design options are endless. Our standard colors are coil-coated for a consistent, long-lasting finish. We also offer custom colors to match your exact specifications.

Our array of cores [corrugated plastic, solid plastic, insulated foam and furniture-grade exterior plywood] as well as the various thicknesses, sheet sizes, and double/single sided sheets satisfy any project. All of our panels can be custom fabricated or cut to your exact dimensions.

STANDARD PANELS

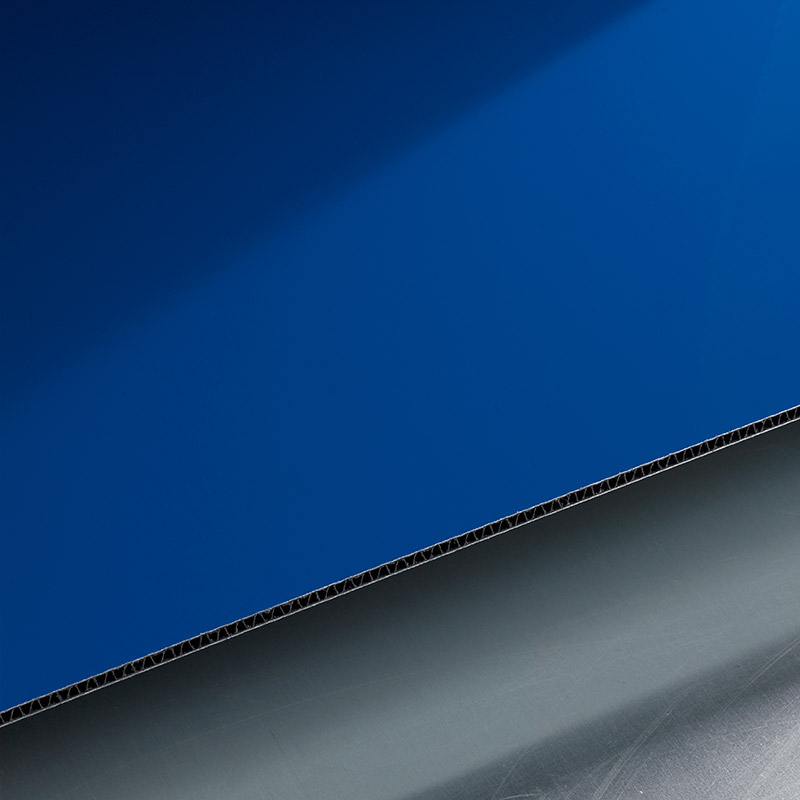

Corrugated Plastic Core Panels

Manufactured in the USA, our polypropylene corrugated plastic core ACM panels feature a double-sided aluminum for stability and strength. Panel thicknesses range from 3mm to 25mm and sizes range from 4’x8’ to 5’x12’. A variety of colors and finishes are available.

Our corrugated plastic core panels are widely used in equipment enclosures, campers/RVs and other automotive applications, partitions, and cleanroom applications. With the added feature of the panels being digital print-ready, the applications are endless.

Solid Core Panels

Solid core ACM panels feature a double or single-sided painted aluminum in varying skin thicknesses bonded to a solid polyethylene core making them rigid yet lightweight. Panel thicknesses range from 2mm to 6mm and the panel size ranges from 4’x8′ to 5’x10′. Colors are available on Omega-Bond Standard only.

Omega-Bond panels are ideal digital print applications and great for use in displays, exhibits and scenery applications. They are also regularly used in campers/RVs and cleanroom applications.

Plywood Core Panels

Wood core panels are constructed with exterior-grade plywood core between finished aluminum sheets that provide strong, dent-resistant panels. Panels are available in 1/4″ and 1/2″ thicknesses and the panel size is 4’x8′. Colors are available for LusterBoard only.

When applications call for standard carpentry techniques, our wood core panels are a good fit.

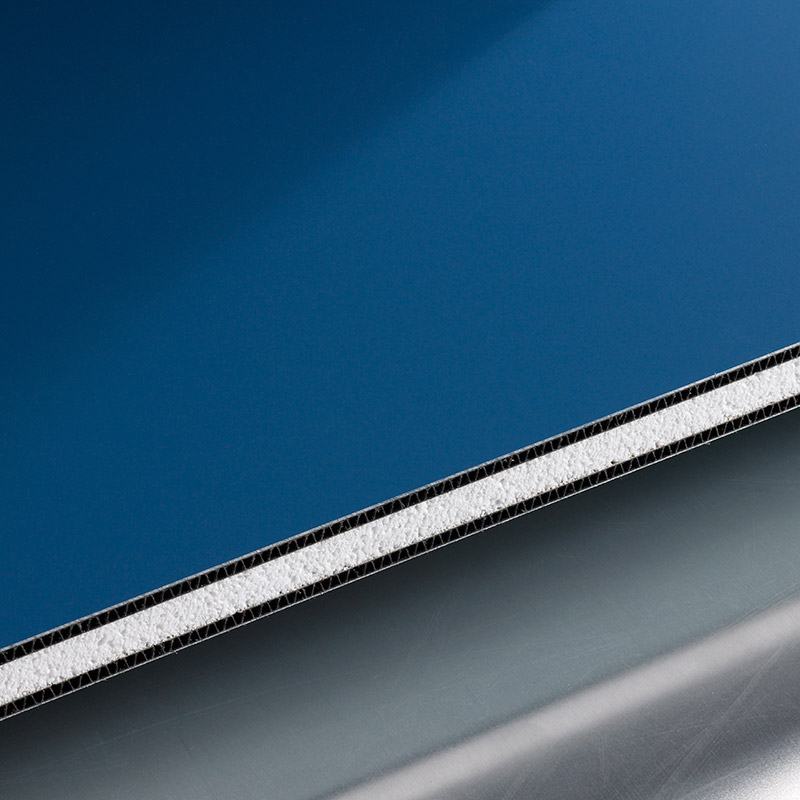

Insulated/Foam Core Panels

Insulated/foam core panels are constructed with an insulating foam core sandwiched between finished aluminum sheets and two corrugated plastic stabilizers or exterior-grade hardboard stabilizers. Available in smooth or stucco-embossed finishes in a variety of colors. Panel thicknesses range from 5/8″ to 3-1/2″ and panel sizes range from 4’x8′ to 4’x12′. A variety of colors and finishes are available.

The insulation aspect of these ACM panels is perfect for HVAC and solar applications.

CUSTOM PANELS

Customizable Composite Panels

Upon request, we can make customized panels to meet your specific application needs. We’re not limited to the traditional aluminum composite panels with our standard core materials. Panels utilizing other types of face materials like fiberglass reinforced plastic (FRP), high-density polyethylene (HDPE), and wood veneer or different core options that offer sound absorption properties, insulative properties, etc. are an option!

Our unique manufacturing process allows us to customize the components to make composite panels just for you.

Why Choose Our Panels?

- Panel thicknesses range from 2mm to 25mm (5/64” to 1”) *

- Sheet sizes range from 4’ x 8’ to 5’ x 12’ *

- Finishes include smooth, stucco-embossed, mill, anodized, matte, and metallic *

- Moisture resistant

- Corrosion resistant

- Chemical resistant

- Strong & lightweight

- Weather-resistant with a “Class A” flame spread rating (some exclusions may apply)

- Field-tested through extensive freeze/thaw cycling tests with no significant structural panel failure

- Wind-resistant — can withstand winds over 120 mph

- Double-side panels for modular/free standing rooms

- Routs and cuts easily using standard carpentry tools; even bends around corners; v-groove & bend for perfect 90° corners

- UL Recognized Component (some exclusions may apply)

- Alternative to aluminum honeycomb panels

- Manufactured in the USA (excludes all Omega-Bond products)

*Contact Laminators for details on panel thickness, sheet sizes and finishes as not all apply for each product/color.

COMPOSITE PANELS BROCHURE

All of our standard products can be customized to your specifications.