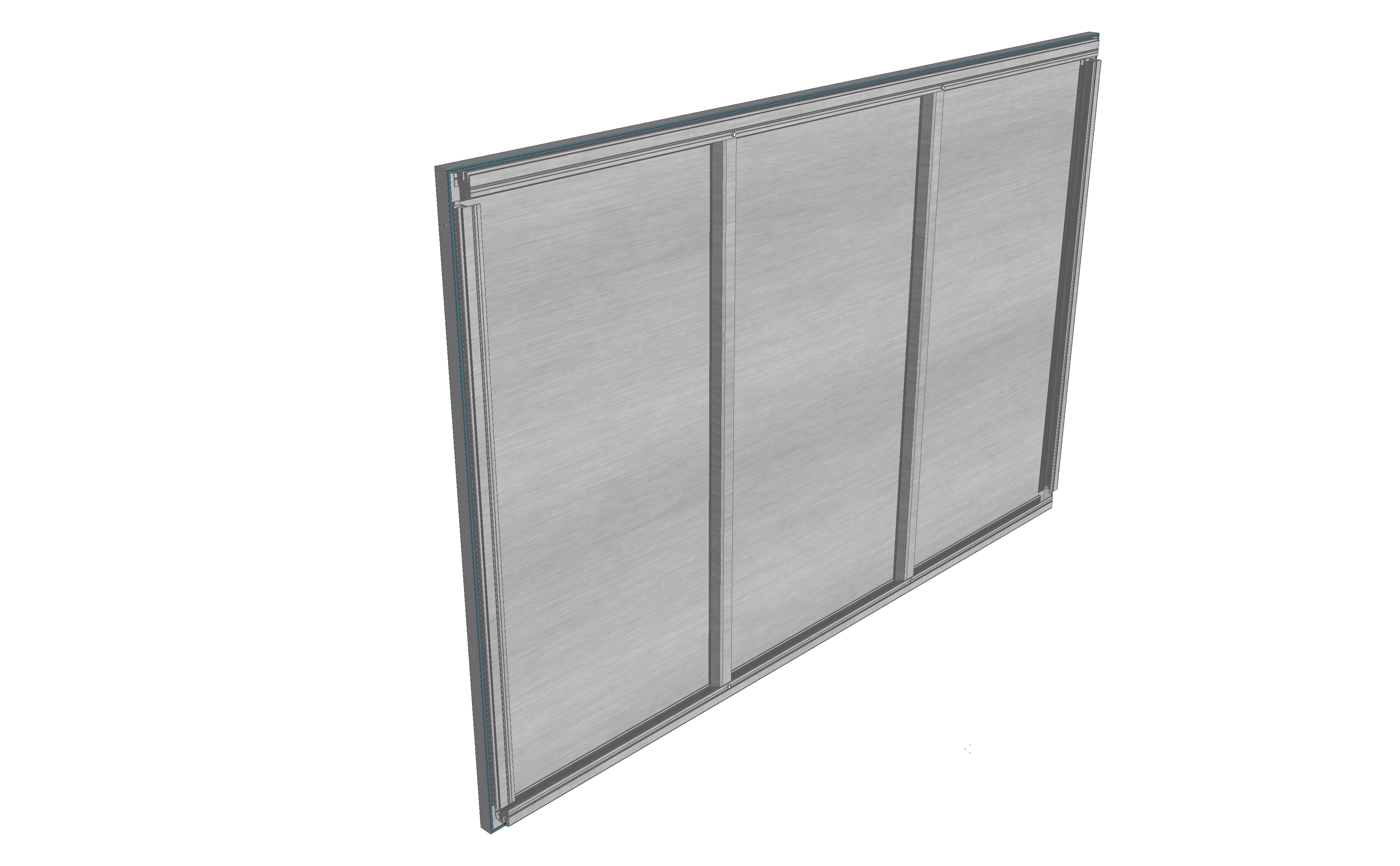

AdaptaClad® RS is an extremely adaptable, easy-to-use rainscreen installation system designed to utilize our NEW Omega-Lite® FR ACM panels.

This new shop-fabricated system provides significant time and labor savings to fabricators and installers.

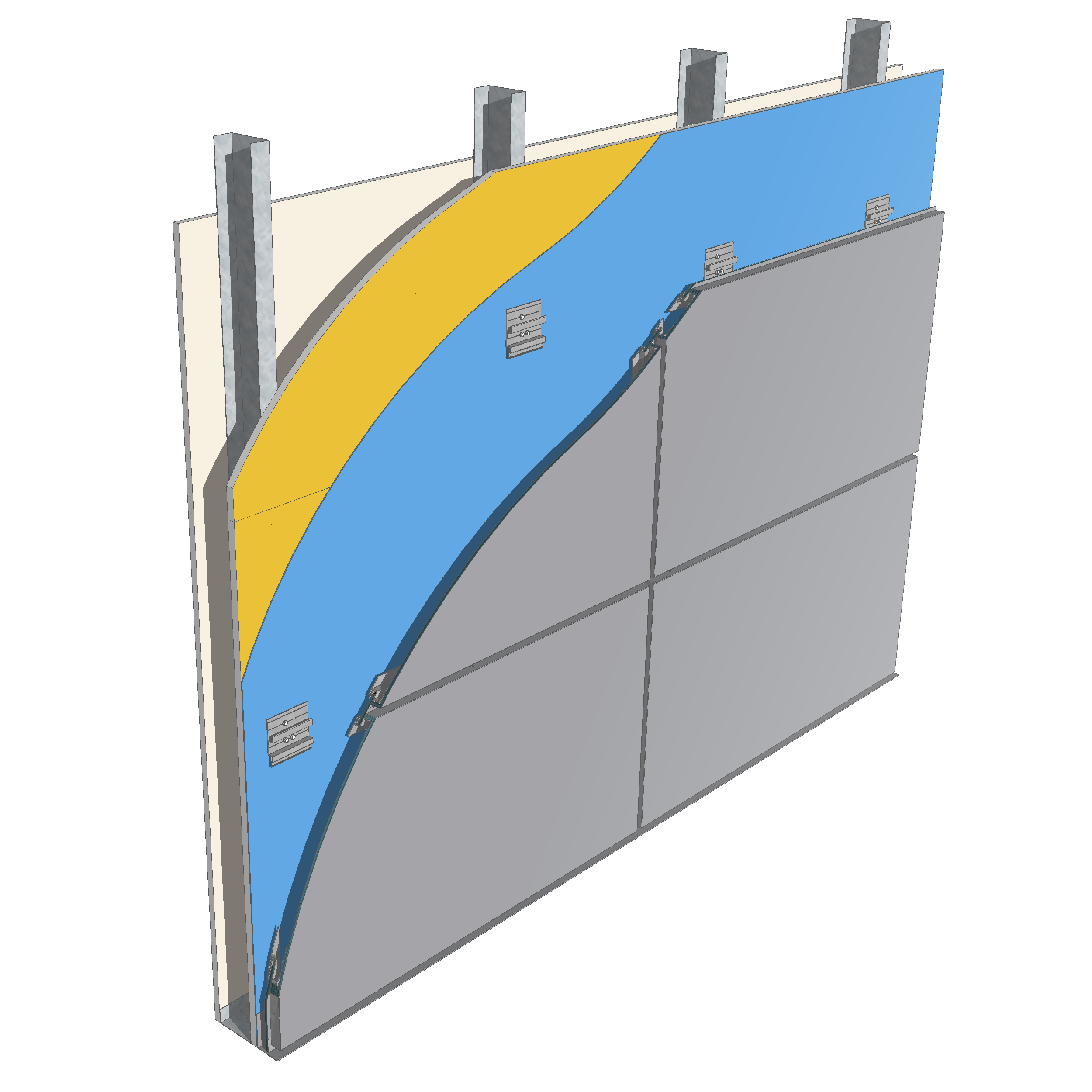

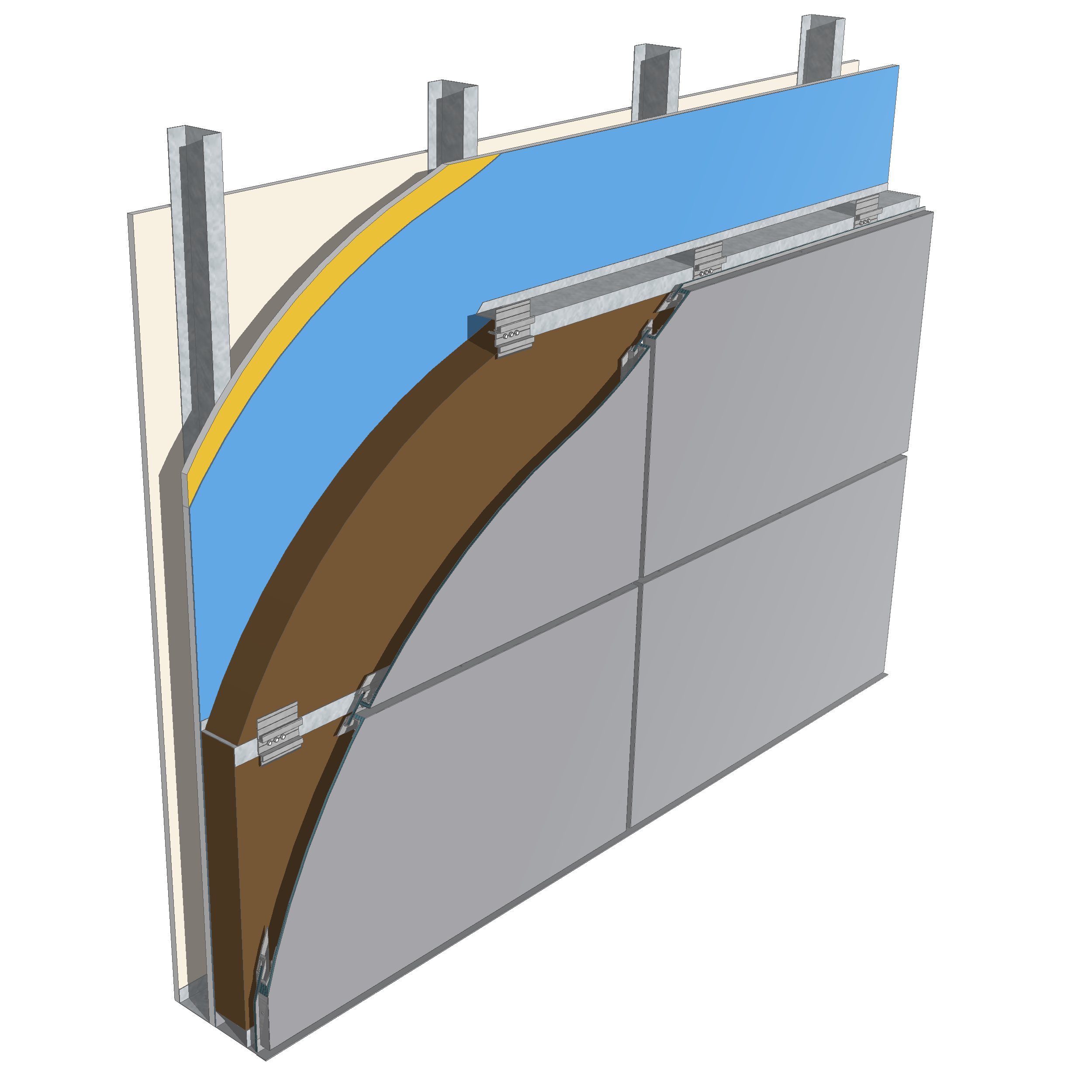

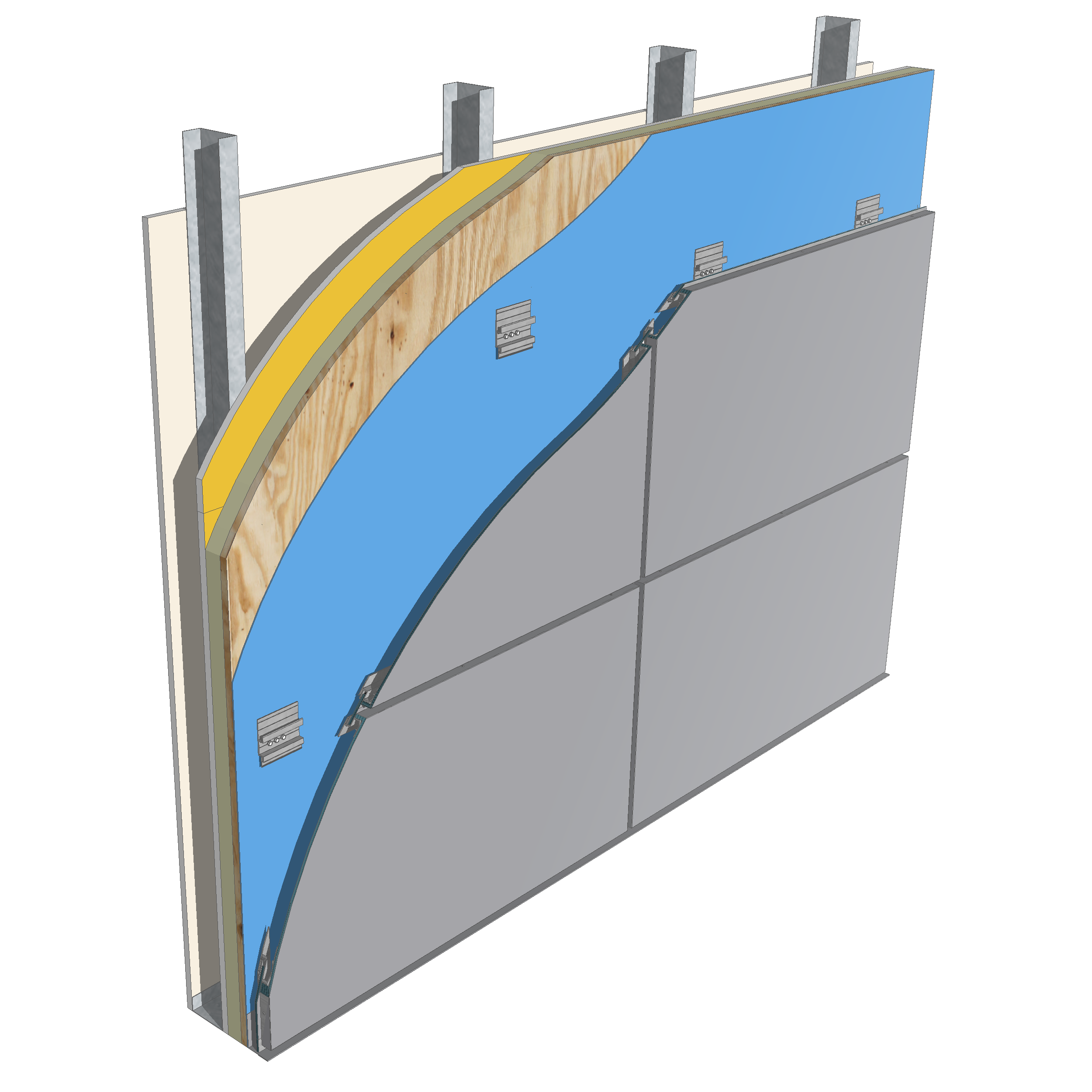

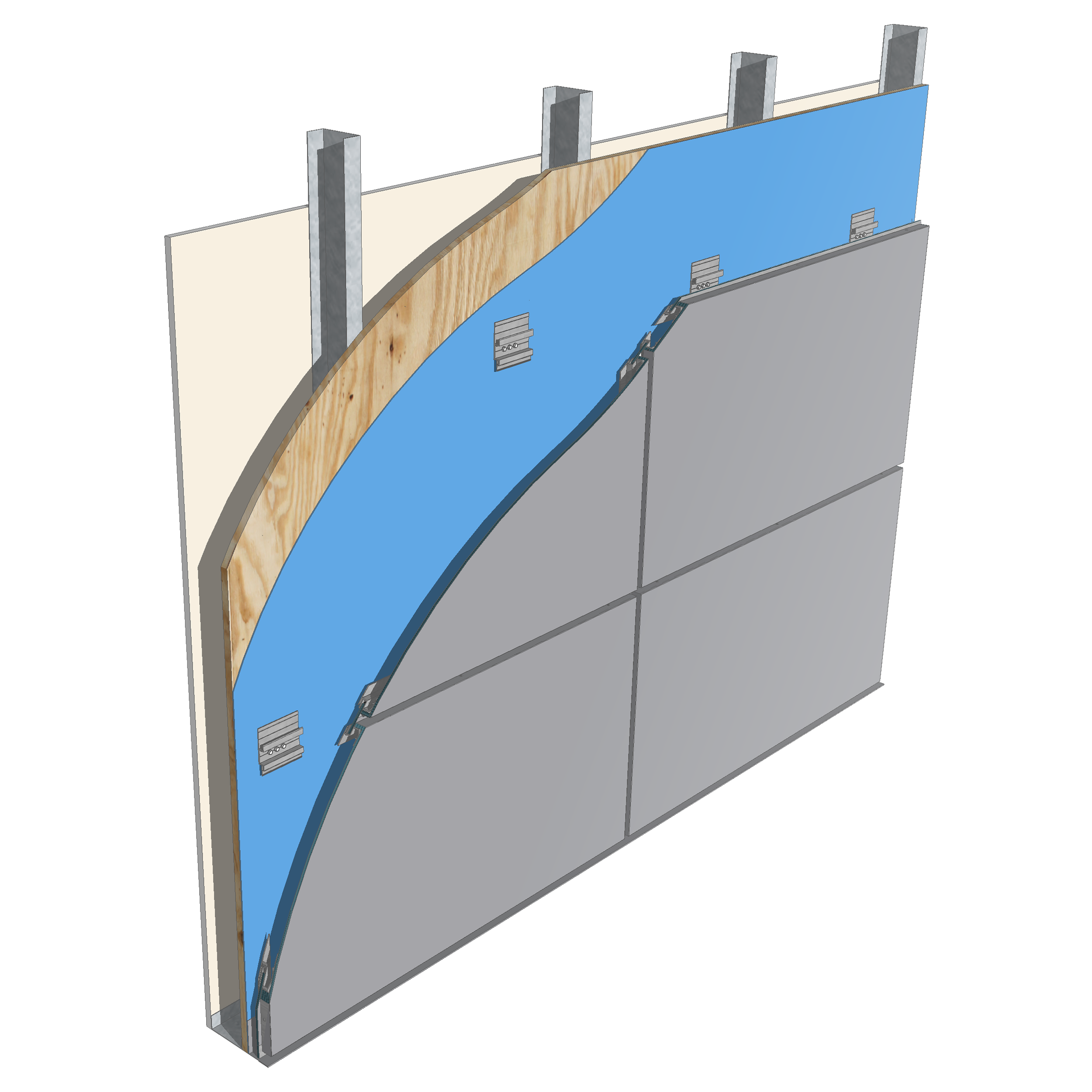

AdaptaClad RS is a weather-resistant exterior wall cladding panel system that combines a modern reveal-joint aesthetic with drained and back ventilated rainscreen performance. It can be installed over a variety of substrates and on projects requiring Continuous Insulation (CI), such as our Omega CI® rigid insulation panels or third-party CI solutions.

PORTFOLIO

View Projects Using AdaptaClad RS Installation System

VIDEOS

AdaptaClad RS Burn Test

AdaptaClad RS Launch

AdaptaClad RS utilizes our NEW Omega-Lite FR ACM panels, aluminum panel extrusions and clips, and accessories

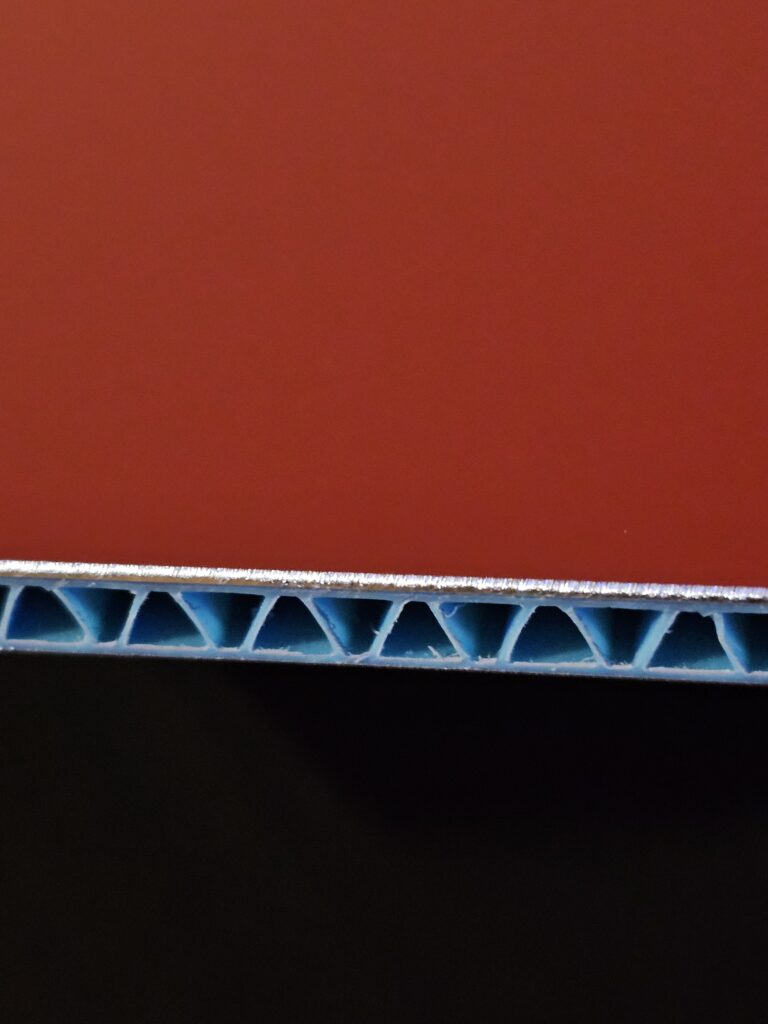

Omega-Lite FR consists of a corrugated thermoplastic core with fire-resistant additive bonded to a finished aluminum sheet on one face and a protective mill finished sheet of aluminum on the other.

With a multitude of standard colors and various finishes, your design options are endless; we also offer custom colors to match your exact specifications.

Omega-Lite FR provides a decorative, strong, durable surface finish for exterior wall surfaces and is non-absorbent, water-resistant, and easy to maintain.

ADAPTACLAD RS FEATURES / BENEFITS

- Built-in adaptability to install over almost any building substrate

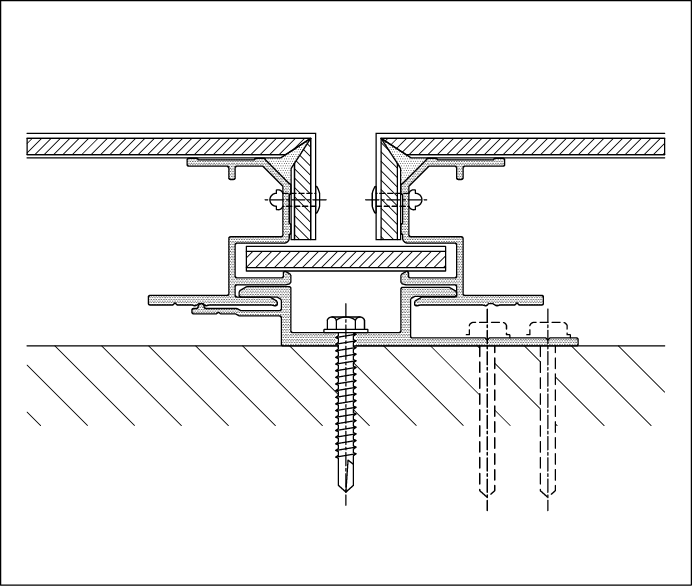

- Simple-hang installation requiring mechanical attachment on only two sides of the panel module

- Rainscreen system with an open dry joint design characterized by a deep reveal terminated with an insert strip installed without the use of caulks or adhesives

- Dry joint aesthetic with customizable joint width from 9/16″ (standard) up to 4″

- Utilizes continuous perimeter extrusions that provide versatility on stiffener and clip locations

- Economical baseline system design for typical projects requiring up to 30 psf (ASD) wind loads; easily adapted to higher wind load requirements

System Testing

- NFPA 285 (Fire Performance)

- AAMA 509 (Drainage & Ventilation)

- ASTM E283 (Rate of Air Leakage)

- ASTM E331 (Water Penetration)

- ASTM E330 (Structural Performance)

Advantages of AdaptaClad RS over Laminators’ previous Dry Seal installation system

Minimized overall material costs

- Simplified design utilizes proprietary perimeter extrusions to provide versatility on panel stiffener and clip locations

- No supplemental rails or strapping needed

Minimized shop fabrication labor

- No mitered corners required for perimeter extrusions, saving approximately 8 minutes per panel

- No shims needed to support saw cut of perimeter extrusions

- Fab sealant relief is designed into the extrusions

- Silicone press-in soffit vent vs. labor-intensive sealed slot with a riveted metal screen

Minimized field installation labor

- No adhesive in the field of panels

- No foam tape along panel joints

- No field-installed panel stiffeners

- Extremely adaptable to installation over various substrate scenarios

Tested with new Omega-Lite FR panels to current NFPA 285 standard

- No longer prohibits vertical joints above window openings