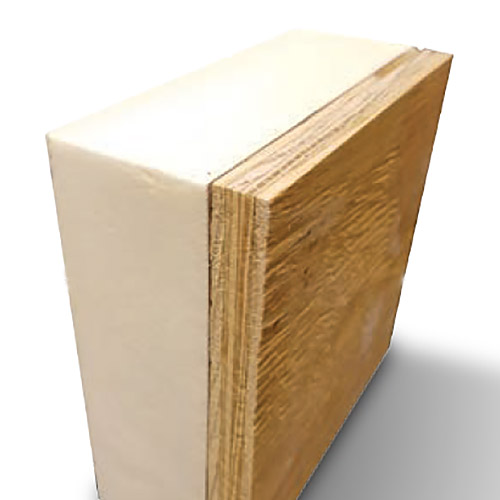

Omega CI is a rigid insulation panel comprising a closed-cell polyiso foam core bonded to a premium performance coated glass backer and a 5/8” fire-treated plywood face. Omega CI is available in 4’ x 8’ sheets in 2.1” thickness (contact Laminators technical support for alternative thickness availability).

The plywood layer provides a dimensionally stable substrate by normalizing attachment loads (avoiding deformation of the rigid foam insulation) and is also fire-treated to allow for NFPA 285 compliance.

The foam insulation layer provides thermal resistance to achieve the desired R-value for the wall assembly without causing thermal bridging.

APPLICATIONS

Installations requiring continuous insulation

PORTFOLIO

View Projects Using Architectural Systems Panels

VIDEOS

Omega® CI Rigid Insulation Panels

Features

- 2.1″ thickness provides R-9.6 for IECC/ASHRAE 90.1 prescriptive continuous insulation requirement

- Class A fire rating and NFPA 285 compliant for installations on Type I, II, III, and IV construction

Benefits

- Ease of installation: product is installed in a similar manner to traditional plywood sheathing

- Labor savings: combines the installation of continuous insulation and structural sheathing into one component

- Single-source responsibility for product delivery

- Simplifies attachment of ACM veneer systems by providing a continuous structural substrate