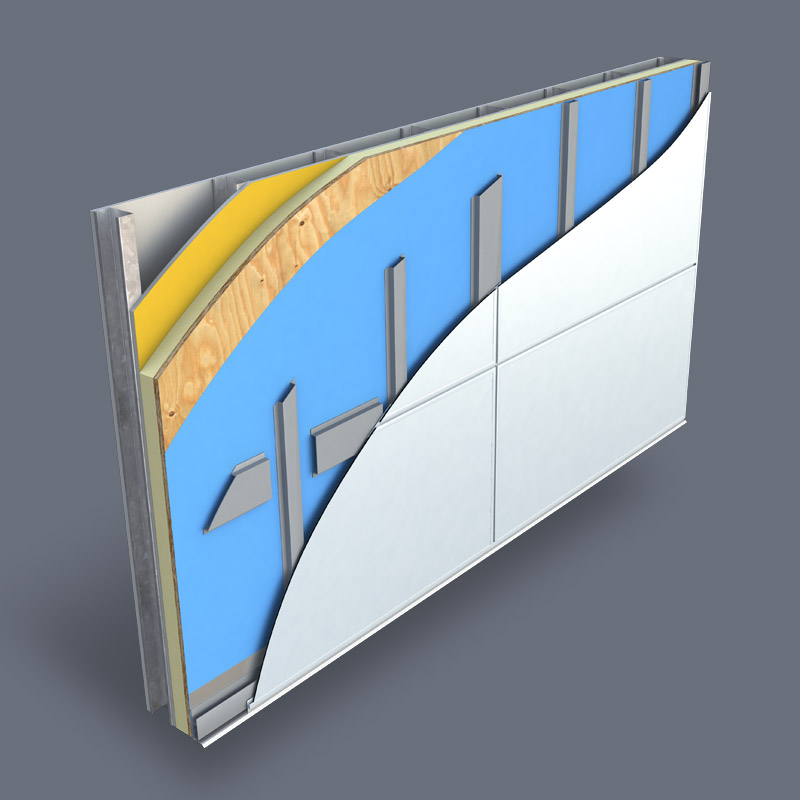

Our drained and back-ventilated field-fabricated installation systems provide designers and installers with the optimal solution to meet the challenges associated with achieving a code-compliant exterior wall envelope.

Before we present the details of the solution, let’s examine the complexity of these code challenges.

Aluminum Composite Material (ACM) panels are commonly used as the aesthetic covering for the exterior wall portion of a building envelope.

The exterior wall envelope plays a multi-functional role in the performance of the overall building envelope and must accomplish the following:

- Manage moisture flow (liquid water and water vapor) through the exterior wall

- Minimize the impact of exterior air temperature on interior conditioned space

- Retain the majority of building-generated heat or conditioned air

- Control the spread of fire across the exterior

- Provide structural support for an aesthetic veneer system

The International Building Code (IBC) has established performance requirements for water management, thermal performance, and fire resistance for exterior wall envelopes. Unfortunately, complying with these building code performance requirements forces designers and installers into a complex balancing act. Meeting any one performance requirement in isolation of the others can lead to a conflict or unbuildable condition. Achieving a code-compliant ACM veneer assembly often requires the use of proprietary solutions that involve complex detailing and planning, thereby increasing labor and material costs while reducing the flexibility for making adjustments during construction.

RESOURCES

Field-Fabricated Installations Systems Brochure »

1-Piece, Tight-Fit Molding System Guide »

Field-Fabricated Panel Systems Specification (1-Piece, Tight-Fit and Clip & Caulk – BDV) »

Continuous Insulation Specification (Omega CI) »

1-Piece, Tight-Fit Molding Technical Data Sheet (BDV) »

VIDEOS

Back-Drained and Ventilated Clip & Caulk™ Installation System

Back-Drained and Ventilated 1-Piece, Tight-Fit Molding Installation System

Omega CI® Rigid Insulation Panel

UNDERSTANDING CODE REQUIREMENTS

THE OPTIMAL SOLUTION: BACK-DRAINED & VENTILATED + OMEGA CI®

LEARN MORE

Need a quick budget number but can’t wait for a take-off? Let us help!

Submit our Budget Pricing Request Form and we’ll provide you with estimated quantities and budget numbers for your upcoming project.