For more than 15 years, we’ve partnered with cleanroom specialists to supply aluminum composite panels for wall and ceiling systems.

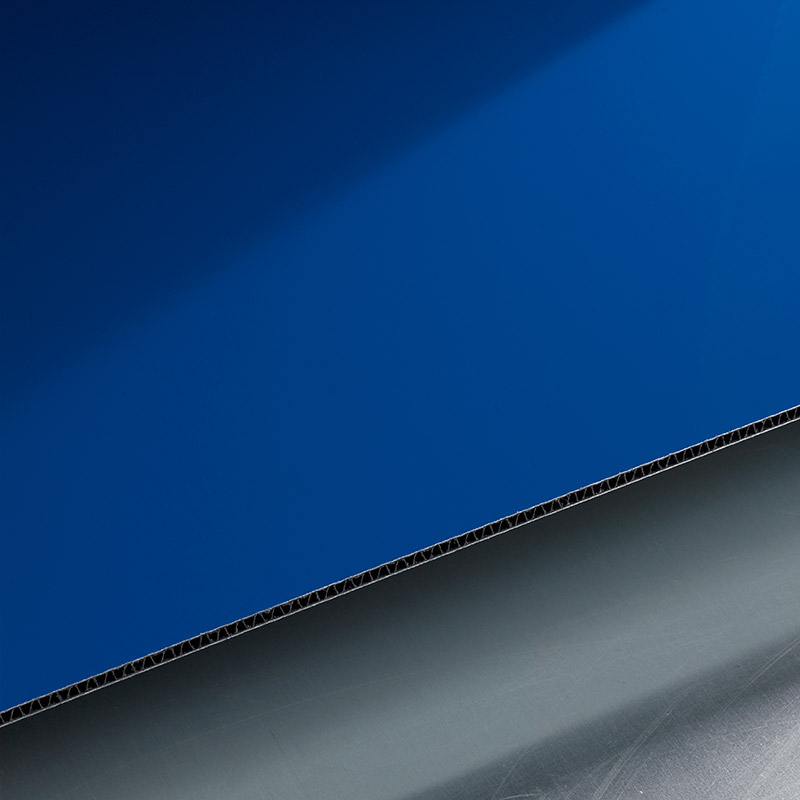

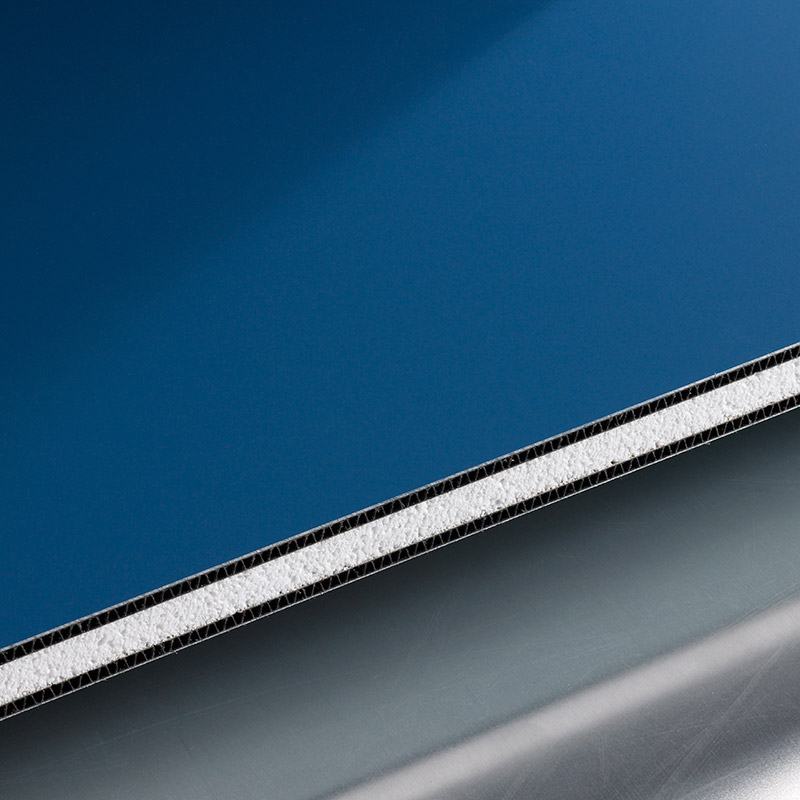

Our ACM panels are strong, lightweight, and moisture-resistant, featuring painted aluminum facings bonded to corrugated polypropylene, solid polyethylene, or insulated cores. Aluminum skins on both sides provide exceptional rigidity and durability, while resisting swelling, corrosion, rot, water wicking, and delamination—making them well suited for cleanroom environments.

Common panel selections for cleanroom systems include Alumalite (Standard and Economy), Omega-Bond (Standard, Premium, and Economy), and Thermolite.

Fabrication & Installation

Our panels are designed for efficient on-site fabrication using standard carpentry tools. This allows cleanroom assemblies to be designed and installed without complex engineering drawings or shop fabrication. To further streamline installation, we can cut panels to your exact project requirements.

Finish

Depending on the panel selected, finished surfaces include high-gloss, factory-baked PVDF (Kynar 500) or polyester-painted aluminum on both sides – delivering a smooth, durable, and easy-to-clean finish. These surfaces are warranted against cracking, chipping, flaking, or peeling. For high-impact or high-wear applications, we also offer panels with a durable PVC skin in place of aluminum, ideal for doors and other demanding environments.

Why Choose Our ACM Panels?

- Lightweight

- Moisture resistant

- Corrosion resistant

- Chemical resistant

- On-site fabrication

- Class A flame spread

- Alternative to aluminum honeycomb panels

- Double-sided panels for modular/free standing rooms

- V-groove & bend for perfect 90° corners